Gemeinsam sind wir besser - Better Together! Wir sind jetzt weltweit unter dem Namen Texmo Blank tätig. Weitere Informationen finden Sie auf unserer neuen Website:

Bis zum Start der Vollversion unserer neuen Website, bietet diese Seite weiterhin Informationen rund um Feinguss und zu den Stellenangeboten.

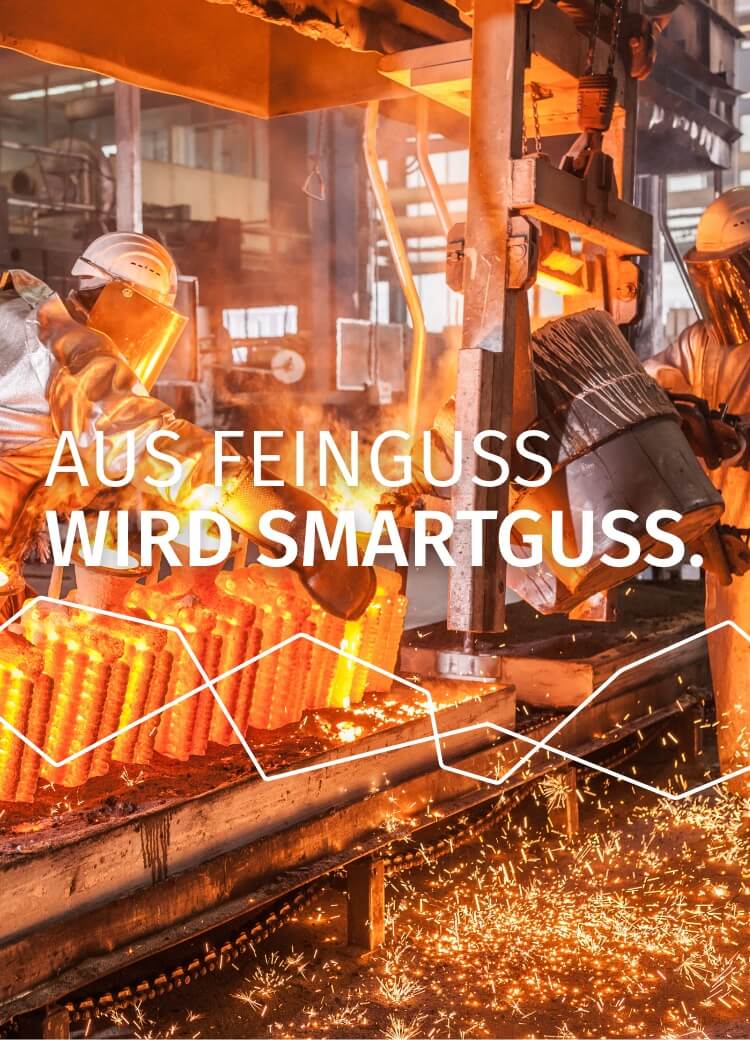

FEINGUSS BLANK: smarte Ideen für Ihre Branche

Smarte Ideen für Ihre Industrie

Unsere vielfältigen Produkte kommen in vielen Branchen zum Einsatz. Hier eine Übersicht zu möglichen Anwendungsbereichen:

Die Zukunft wird heute entwickelt

Die Branche ist im Wandel, wir entwickeln Ihnen zukunftsfähige Technologien - smart!

Übersicht AutomotiveFeuer und Flamme für Feinguss

Neues von FEINGUSS BLANK

Das macht uns smart

SMARTGUSS ist das Versprechen, Sie noch besser zu beraten, Sie noch effizienter zu machen, Sie noch weiter voranzubringen. Einfach gesagt, Sie gemeinsam mit uns smart zu machen.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSSZahlreiche internationale Unternehmen zählen zu unserem Kundenstamm.

Aus gutem Grund: Wir verfügen über breitgefächertes Branchenwissen – und garantieren eine umfassende Betreuung von der Idee bis zur Finalisierung jedes Projekts.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSSHochinnovative Produkte, die in puncto Vielfalt, Qualität und Wirtschaftlichkeit ihresgleichen suchen.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSSUnser Geheimnis: Ganz gleich, wie komplex eine Idee oder ein Projekt auch ist – dank unseres herausragenden Erfahrungsfundus finden wir stets die optimale Lösung.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSSIhre Zufriedenheit steht für uns im Mittelpunkt. Deshalb gehen wir auch beim Thema Service keine Kompromisse ein: Mit immer neuen Angeboten stellen wir sicher, dass Sie sich Ihren eigentlichen Aufgaben widmen können.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSSEgal, ob Auszubildender oder Meister, ob Lagerist oder Entwicklungsingenieur – unsere mehr als 800 Mitarbeiter sind Feuer und Flamme für Feinguss.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSSDas macht uns smart

- SMARTGUSS

SMARTGUSS ist das Versprechen, Sie noch besser zu beraten, Sie noch effizienter zu machen, Sie noch weiter voranzubringen. Einfach gesagt, Sie gemeinsam mit uns smart zu machen.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSS - SMARTER PARTNER

Zahlreiche internationale Unternehmen zählen zu unserem Kundenstamm.

Aus gutem Grund: Wir verfügen über breitgefächertes Branchenwissen – und garantieren eine umfassende Betreuung von der Idee bis zur Finalisierung jedes Projekts.Sie wollen mehr erfahren?

Mehr zu SMARTGUSS - SMARTE PRODUKTE

Hochinnovative Produkte, die in puncto Vielfalt, Qualität und Wirtschaftlichkeit ihresgleichen suchen.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSS - SMARTES KNOW-HOW

Unser Geheimnis: Ganz gleich, wie komplex eine Idee oder ein Projekt auch ist – dank unseres herausragenden Erfahrungsfundus finden wir stets die optimale Lösung.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSS - SMARTER SERVICE

Ihre Zufriedenheit steht für uns im Mittelpunkt. Deshalb gehen wir auch beim Thema Service keine Kompromisse ein: Mit immer neuen Angeboten stellen wir sicher, dass Sie sich Ihren eigentlichen Aufgaben widmen können.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSS - SMARTES TEAM

Egal, ob Auszubildender oder Meister, ob Lagerist oder Entwicklungsingenieur – unsere mehr als 800 Mitarbeiter sind Feuer und Flamme für Feinguss.

Sie wollen mehr erfahren?

Mehr zu SMARTGUSS