We are better together! And, we now operate globally under the name Texmo Blank. You can find more information on our new website:

Until we launch the full version of our new website, you will continue to find details about investment casting as well as jobs vacancies on this page.

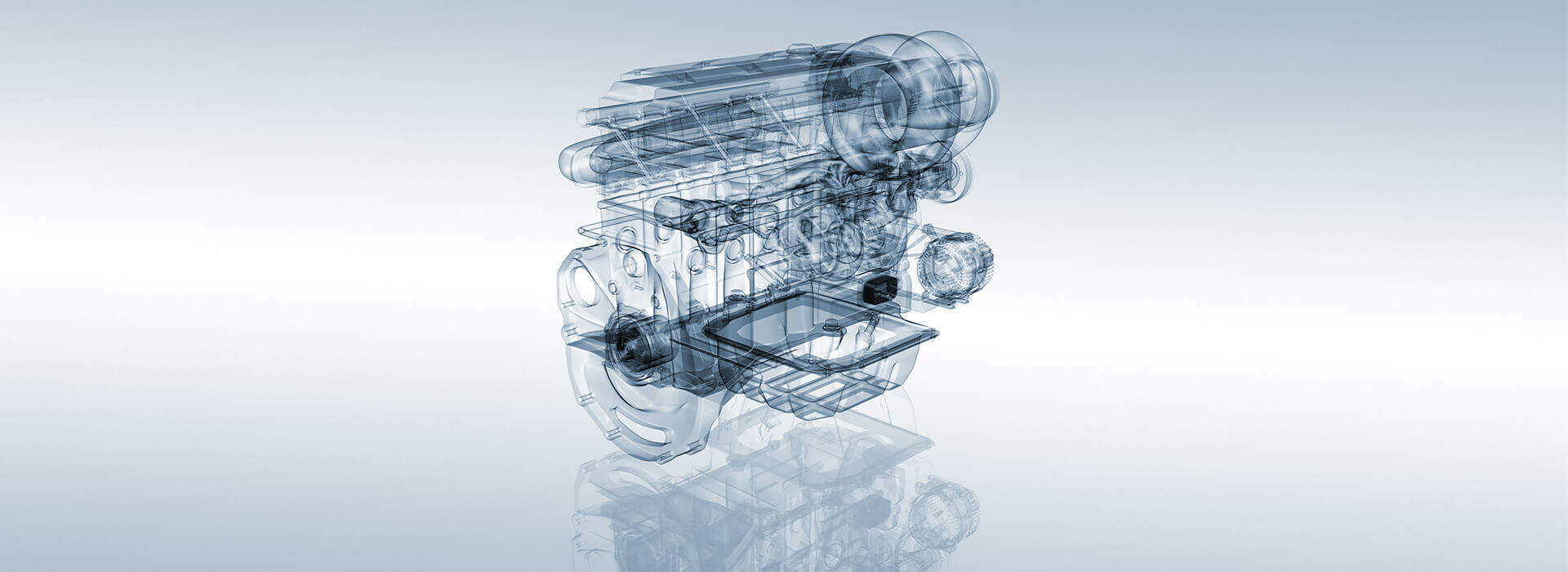

Turbocharger technology

Turbochargers significantly increase efficiency in the vehicle and improve exhaust gas quality. Our highly innovative wastegate systems and turbine wheels contribute significantly to the implementation of modern turbochargers. High-temperature resistant as well as hot-gas-corrosion resistant materials and alloys offer the best prerequisites for implementation in our precise manufacturing and assembly processes.

An exhaust gas turbocharger basically consists of a compressor and a turbine. The exhaust gases that escape after combustion drive the turbine. The connection via a shaft simultaneously drives the compressor wheel, which compresses the intake air and thus delivers a larger mass of air into the combustion chambers of the cylinders. The effects are higher engine power, higher torque, reduced fuel consumption and lower emission values than with comparable naturally aspirated engines.

For optimal functioning of the exhaust gas turbocharger, boost pressure control is necessary. An unregulated turbocharger has a very narrow operating range for good efficiency. Without a wastegate system, there may be a loss of intake pressure. Uniform boost pressure and thus the absence of "turbo lag" is made possible by a so-called wastegate system. This allows the boost pressure to be flexibly adjusted in any situation. It is important that the flap plate is 100% tight - it needs an exact degree of mobility for optimal functioning, which we at BLANK can realise perfectly!

Do you like to realize a smart planning together with us?

Please contact us!

Contact

FEINGUSS BLANK GmbH

Sales

sales@feinguss-blank.com

P: +49 7371 182-0

product examples

Turbine wheel

Exhaust gas turbocharger for cars

The turbine wheel shown is used in the exhaust area of a turbocharger. There are various blade arrangements, such as radial turbines, axial turbines, RFT (Radial Flow Turbines) or MFT (Mixed Flow Turbines). In the latter variant, the so-called "leading edges" are not on a constant diameter, in contrast to the radial turbine. The inclination goes from the housing to the hub and results in a decrease in diameter. As a result, this type of turbine has a higher ratio of vacuum capacity to mass moment of inertia.

Compression in a turbocharged engine often takes place in a radial compressor stage. The air-oxygen mixture is drawn in via the engine's air filter. The spiral housing represents the collecting organ for the distribution of the mass flow. After compression, the air is cooled in an intercooler and fed into the combustion chamber. After combustion, the gas flows out of the cylinder and via the exhaust manifold into the turbine housing. Here, the component is exposed to temperatures of up to 1050 °C. The speed of the turbine wheel in combination with the temperature conditions leads to an immense load on the component. Added to this is the very thin-walled geometry of the blade ends, which require specification conformity of the material. The conditions are best achieved with nickel-based alloys. These are melted and cast in vacuum casting. Casting the turbine wheels and guide systems of drive turbines is an economically and qualitatively appealing manufacturing technique due to the relatively difficult machinability of the alloys and the complex geometries.

material:

Nickel-based alloy

weight:

200 g

Wastegate-System

Exhaust gas turbocharger for cars

Wastegate systems ensure the turbine-side regulation of the boost pressure in exhaust gas turbochargers. The positioning of the exhaust flap in the exhaust system represents an extremely demanding thermal and mechanical load due to the pulsating exhaust gas mass flow. The most important criteria for controlling the boost pressure are precise control of the specified opening angle and a fast response to its change.

The temperatures of the loader as well as the wear behaviour of the component are the critical variables in the development of the flap plate, which we have successfully solved. By using a suitable material and developing an optimal geometry, it was possible to achieve a high-performance solution, not only in casting, but also in the area of mechanical processing and assembly.

material:

Nickel-based alloy

weight:

120 g