We are better together! And, we now operate globally under the name Texmo Blank. You can find more information on our new website:

Until we launch the full version of our new website, you will continue to find details about investment casting as well as jobs vacancies on this page.

back to overview Development partner

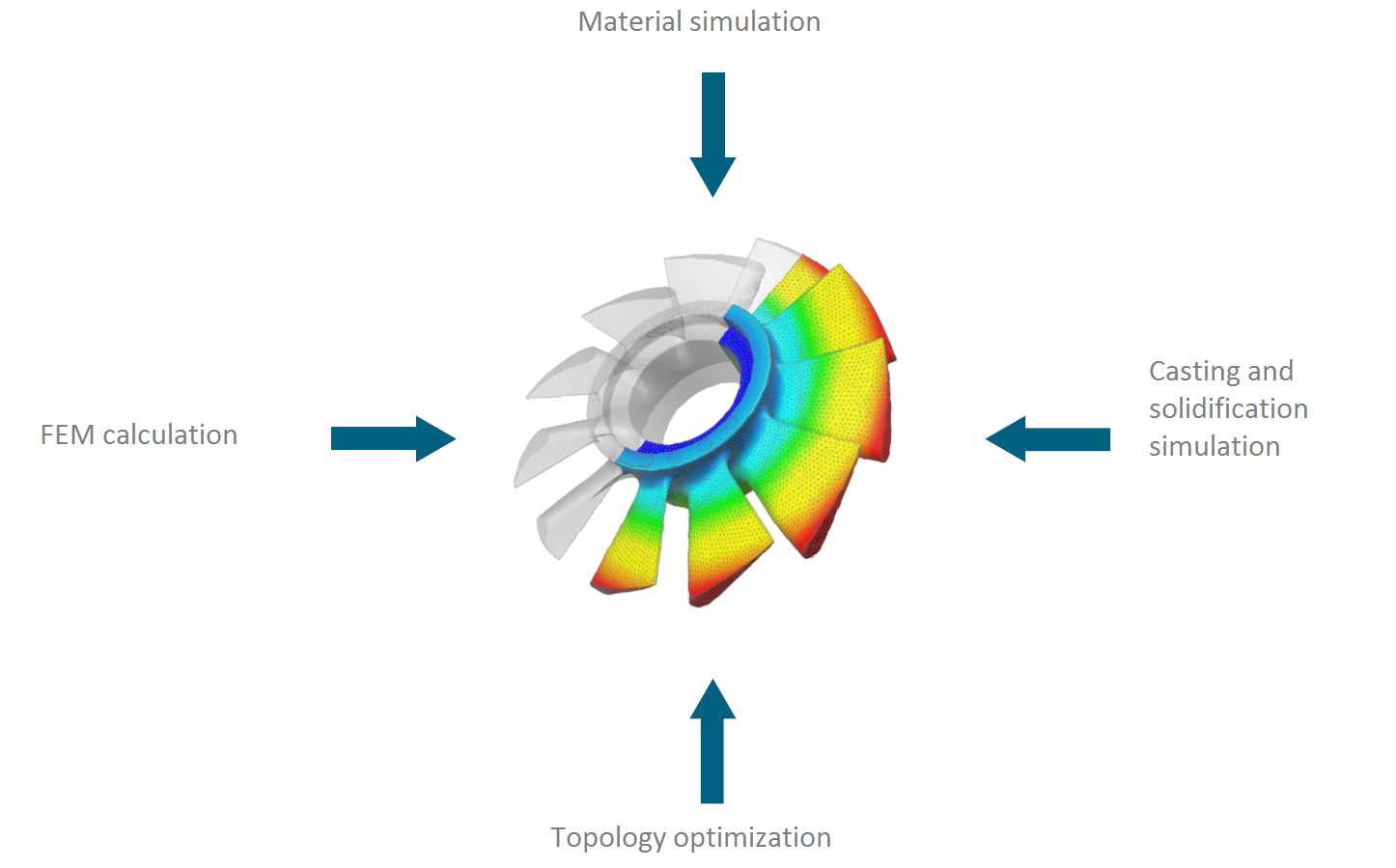

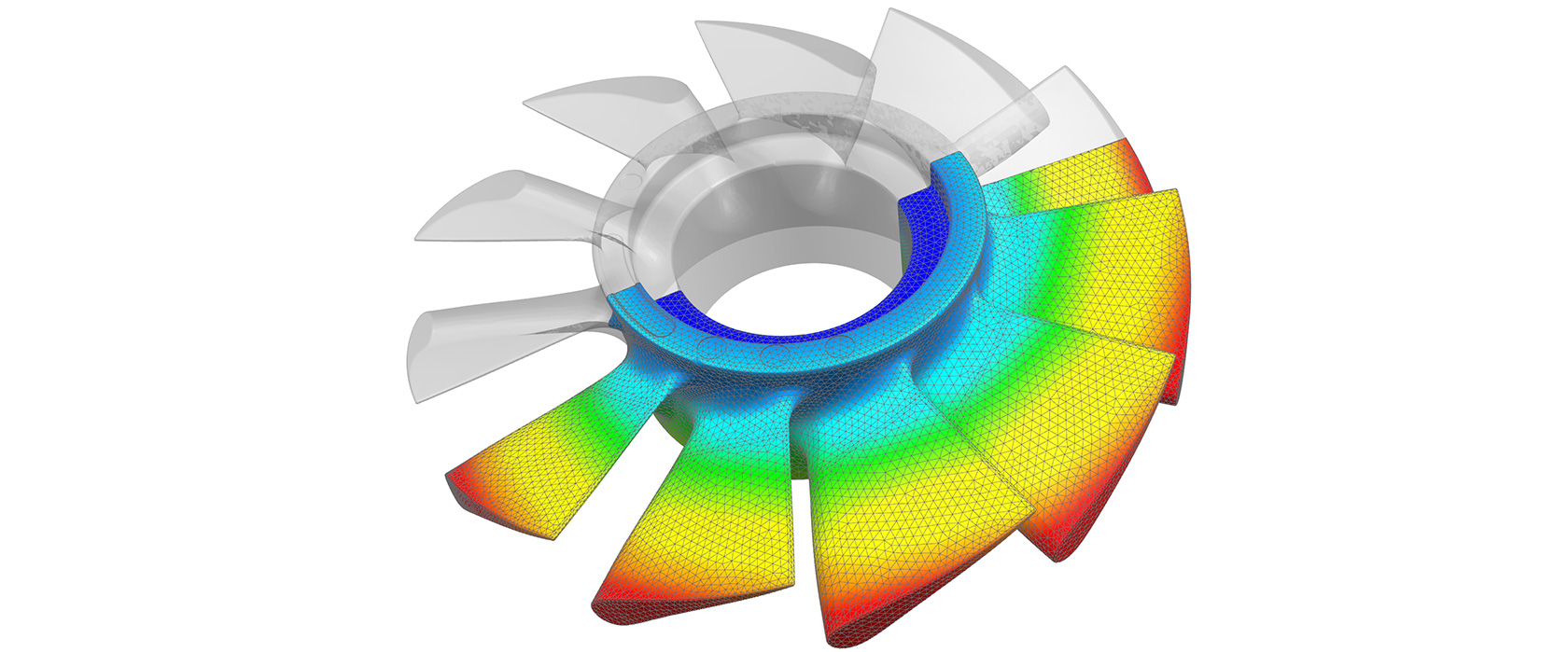

Digital Twin by FEINGUSS BLANK:

Smart development and production by means of new development techniques.

Recognizing and using potentials for improvement before an investment casting part is even produced! Thanks to new development techniques this smart development is now reality at FEINGUSS BLANK! This cost and time saving method is available for you.

You may have many questions related to your parts’ design: Is the geometry of the investment casting part optimal for the intended use? Is it possible to save material? How can the parts be produced most economically? How can the customer’s benefit be increased mutually?

The BLANK-team can answer these questions early in the development process. The Digital Twin by FEINGUSS BLANK is the key to a sustainable customer’s benefit. The application of most modern techniques makes it possible to simulate the essential manufacturing steps and to recognize weak points and eliminate them.

Do you like to realize a smart planning together with us?

Please contact us!

Contact

FEINGUSS BLANK GmbH

Sales

sales@feinguss-blank.com

P: +49 7371 182-0

Possible simulations (among others):

- material simulation

- FEM calculation

- casting and solidification simulation

- topology optimization

Using these different simulations we can offer material recommendations, feasibility studies, and part optimizations.

By using these pre-production methods, the gained knowledge of the different design and prototype phases enable later on in the series an optimal production specific to the customer.

The following properties are efficiently feasible in the investment casting procedure by means of the knowledge of the Digital Twin:

- An attractive, economic process through recognition and use of possible savings with Digital Twin.

- Complex geometries and materials which are difficult to process.

- Simplified processing steps by using intelligent, lightweight materials..

- Reduction of development and development time.

- Weight optimization and associated cost savings.

- Reduced serial production start-up costs.