We are better together! And, we now operate globally under the name Texmo Blank. You can find more information on our new website:

Until we launch the full version of our new website, you will continue to find details about investment casting as well as jobs vacancies on this page.

back to overview Development partner

Functional integration

Many people are often unaware of the fact that a company needs investment casting. For example, parts are produced using alternative production methods such as machining. What many do not know: Intelligent investment casting solutions are often more economical to produce than mechanically machined parts!

Do you like to realize a smart planning together with us?

Please contact us!

Contact

FEINGUSS BLANK GmbH

Sales

sales@feinguss-blank.com

P: +49 7371 182-0

The integration of functions underlines this added value.

At FEINGUSS BLANK, functional integration means optimizing existing parts by making the most of the advantages of the casting process and replacing several cutting parts with an investment casting that fulfills the same function.

Simulations and procedures can be used to ensure that the newly generated investment casting withstands the stresses of the final application process. This ensures the feasibility of the investment casting even before the new production. By using additive manufacturing processes, the customer also has the option of having the new investment casting manufactured and tested by FEINGUSS BLANK prior to actual production. This can also be used to secure the subsequent start of series production.

This service package for the optimization of parts manufactured in alternative processes to generate a new investment casting is summarized as a service package under the term Functional integration.

Application examples:

Sparkling clean with FEINGUSS BLANK!

Smart functional integration in engineering!

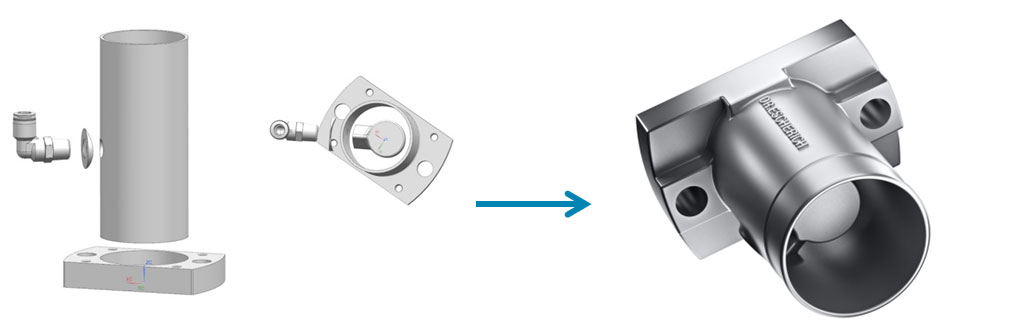

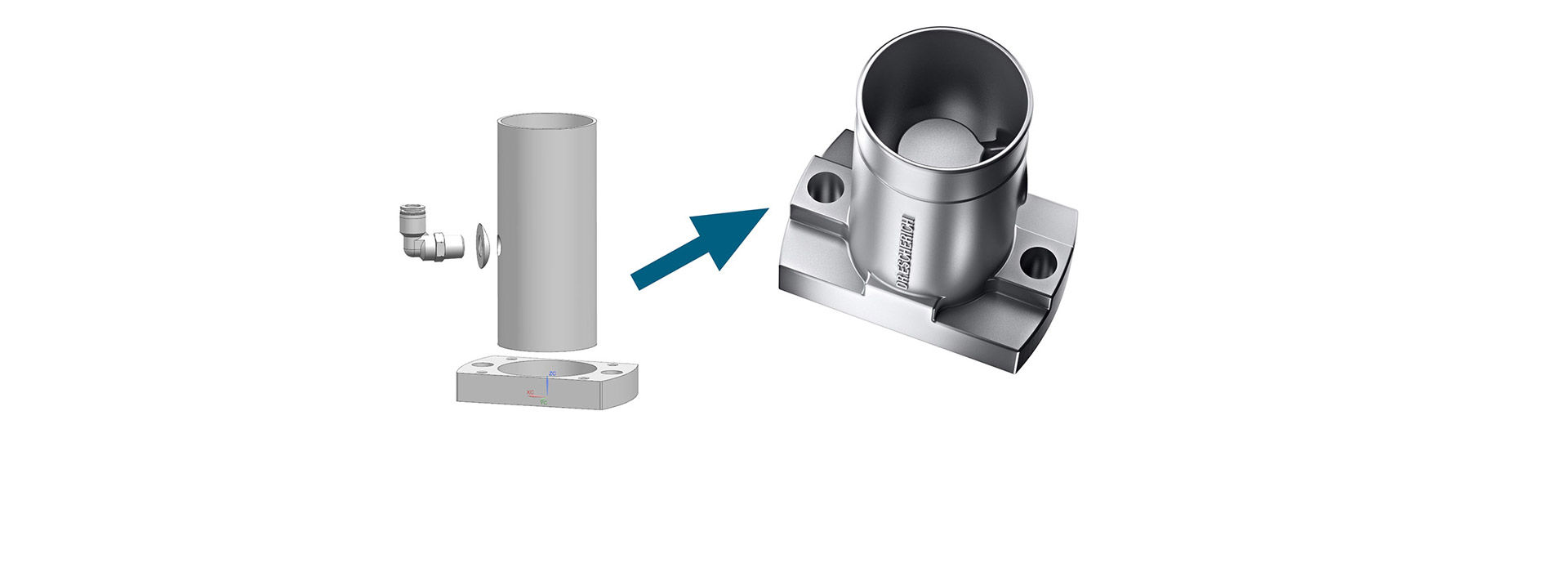

Applying a special contact-free suction technology, the industrial plants of Dr. Escherich GmbH clean objects like cans, cups etc. from dust pigments and smallest particles before filling them with food. The investment casting part of FEINGUSS BLANK is part of the suction technology of the machines. Over an additionally cast-on arm in the inner channel of the stainless steel case, the rotor is put in rotation through a compressed air connection. Using a hose which is attached to the “tube end” of the investment casting part, the desired product is cleaned by means of a suction system.

Until now, due to the demanding function, this component was produced by means of 4 single parts: a base plate, a tube, a milled part (arm) and a turned part (connecting eye). Development partner FEINGUSS BLANK was able to optimize this complex production by reducing the 4 individually manufactured parts to one single investment casting part.

In addition, this reduction from 4 to 1 saved significantly material and costs.

Make one out of 3!

Functional integration at FEINGUSS BLANK

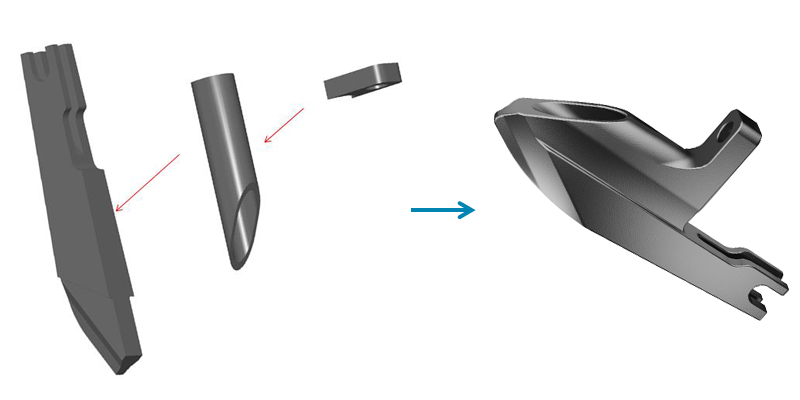

Our customer is specialized in the production of equipment for tillage, seed drilling and harvesting. The enterprise needed a component for their accessory seed drill which can form a regular seed furrow and remove straw and plant residues from the corn storage area.

First the component was manufactured as a welding assembly. Several individual parts made of different material like flat steel were separately machined and welded. This way of production was extensive and costly. When discussing an offer, the developers of FEINGUSS BLANK submitted an alternative proposal for a more economic and more efficient solution than the previous welded component.

The manufacturing by investment casting according to the lost wax procedure made it possible to replace the three individual components, which up to now had to be welded together, by one single investment casting part.

After having delivered the first parts, FEINGUSS BLANK as system supplier additionally took over further manufacturing steps for the whole order and supplied the customer with a ready-to-install component made in one single cast, hardened and lacquered.

So a price reduction of 50% could be achieved compared to the previous welding assembly