We are better together! And, we now operate globally under the name Texmo Blank. You can find more information on our new website:

Until we launch the full version of our new website, you will continue to find details about investment casting as well as jobs vacancies on this page.

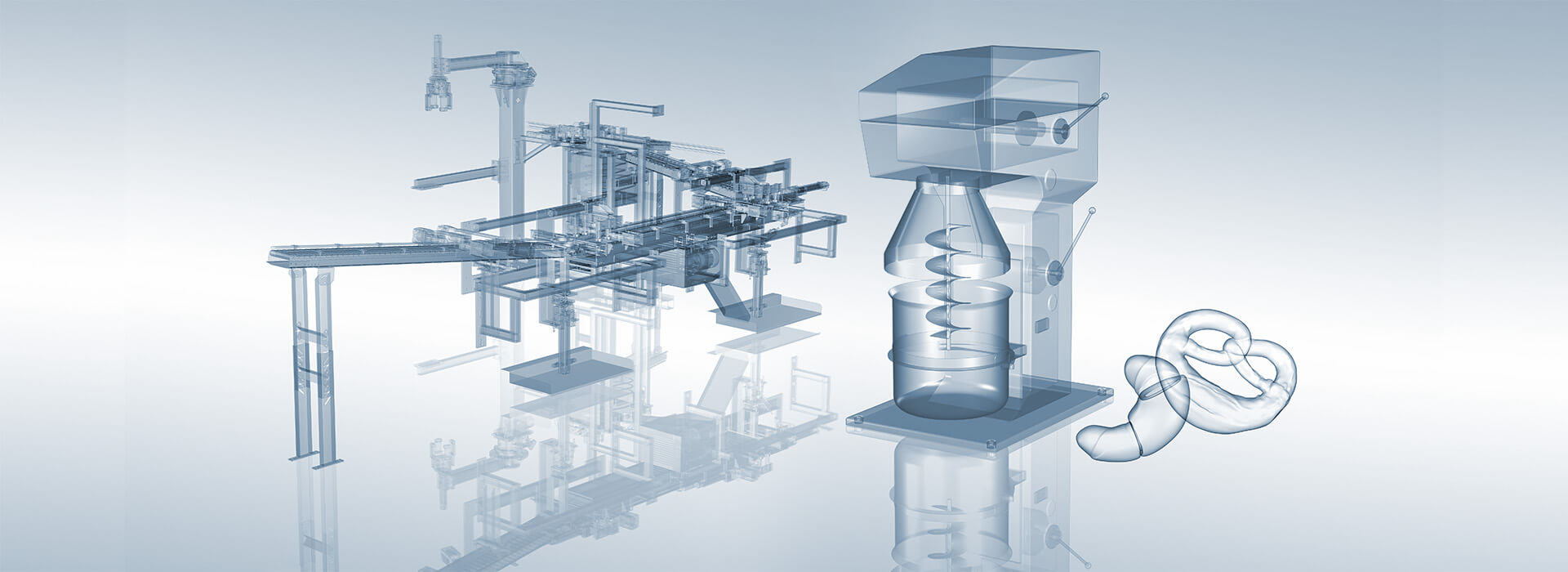

Food and packaging technology

You can rely on the experience and expertise from FEINGUSS BLANK for use in contact with food and other sensitive areas.

- Corrosion resistance

- High surface quality

- Absence of pores

- Wear resistance

- Variety of materials

Do you like to realize a smart planning together with us?

Please contact us!

Contact

FEINGUSS BLANK GmbH

Sales

sales@feinguss-blank.com

P: +49 7371 182-0

In the food and beverage industries, maximum demands are made on resistance to corrosion, lyes and acids. This makes maximum surface quality and absence of pores absolutely essential. Due to the competent, technical application advice and the precision of the process, FEINGUSS BLANK GmbH is a sought-after partner for a wide range of suppliers in food technology. You can trust in us!

The packaging industry is characterised by automated machines and systems which make maximum demands on weight- and strength-optimised components with high wear resistance. Thanks to our variety of materials and the high design freedom offered by investment casting, we are a recognised partner for the development of packaging and foil-stretching machines and in strapping technology. The field of packaging technology is irreplaceable and continuously develops new and innovative solutions.

Productexample

Bell

Surface cleaning system

The most economical, best and safest technical solution is when one function-integrated component is made from several individual parts. This bell used to be made of 4 individual parts, a base plate, a milled part (arm), a tube and a turned part (connecting eye). As a development partner, FEINGUSS BLANK was able to optimise this complex production to just one investment casting. In view of the reduction from 4 components to 1 one component, a significant material and cost saving was able to be realised.

The embedded arm posed a challenge in terms of investment casting, especially regarding feasibility. Due to the small wall thicknesses, care had to be taken that the hot metal completely fills the mould and does not cool down beforehand. FEINGUSS BLANK was able to solve this problem with a special gating technique. Due to the high design freedom of the investment casting process, it provides optimal part variants, among other things for beverage bottling plants, and saves complex joining and assembly processes. More detailed information on this development project can be found under the keyword functional integration.

material:

Steel alloy

weight:

308 g

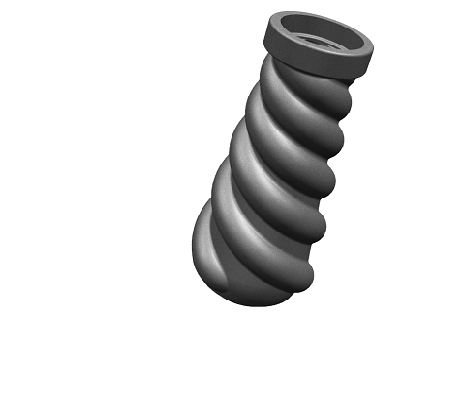

Tower screw

Water treatment unit

The tower screw shown is used in a so-called "biodynamiser", which makes it possible to reprocess tap water and thus reduce the use of plastic bottles. The design of the tower screw follows the movements of the water, giving the water back its natural quality from nature. Particularly the demanding internal geometry of the tower screw led to a realisation in the investment casting process.

material:

Copper alloy

weight:

474 g

Spiral housing

Fresh water pump galley aircraft

This fresh water pump represents a smart solution in the aviation industry. The component combines the weight-saving design necessary for aviation and aerospace with the high demands on corrosion resistance, absence of pores and high surface quality important for the food industry. Our application engineers were able to achieve this balancing act to the complete satisfaction of the customer.

material:

Chrome-nickel-molybdenum steel

weight:

899 g