We are better together! And, we now operate globally under the name Texmo Blank. You can find more information on our new website:

Until we launch the full version of our new website, you will continue to find details about investment casting as well as jobs vacancies on this page.

Importance of investment casting

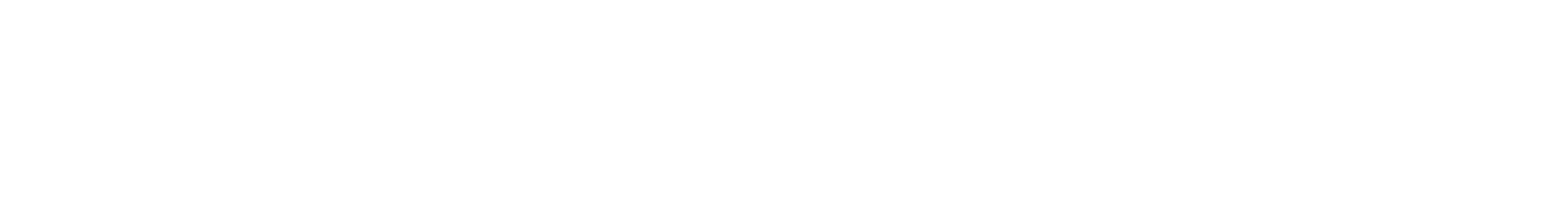

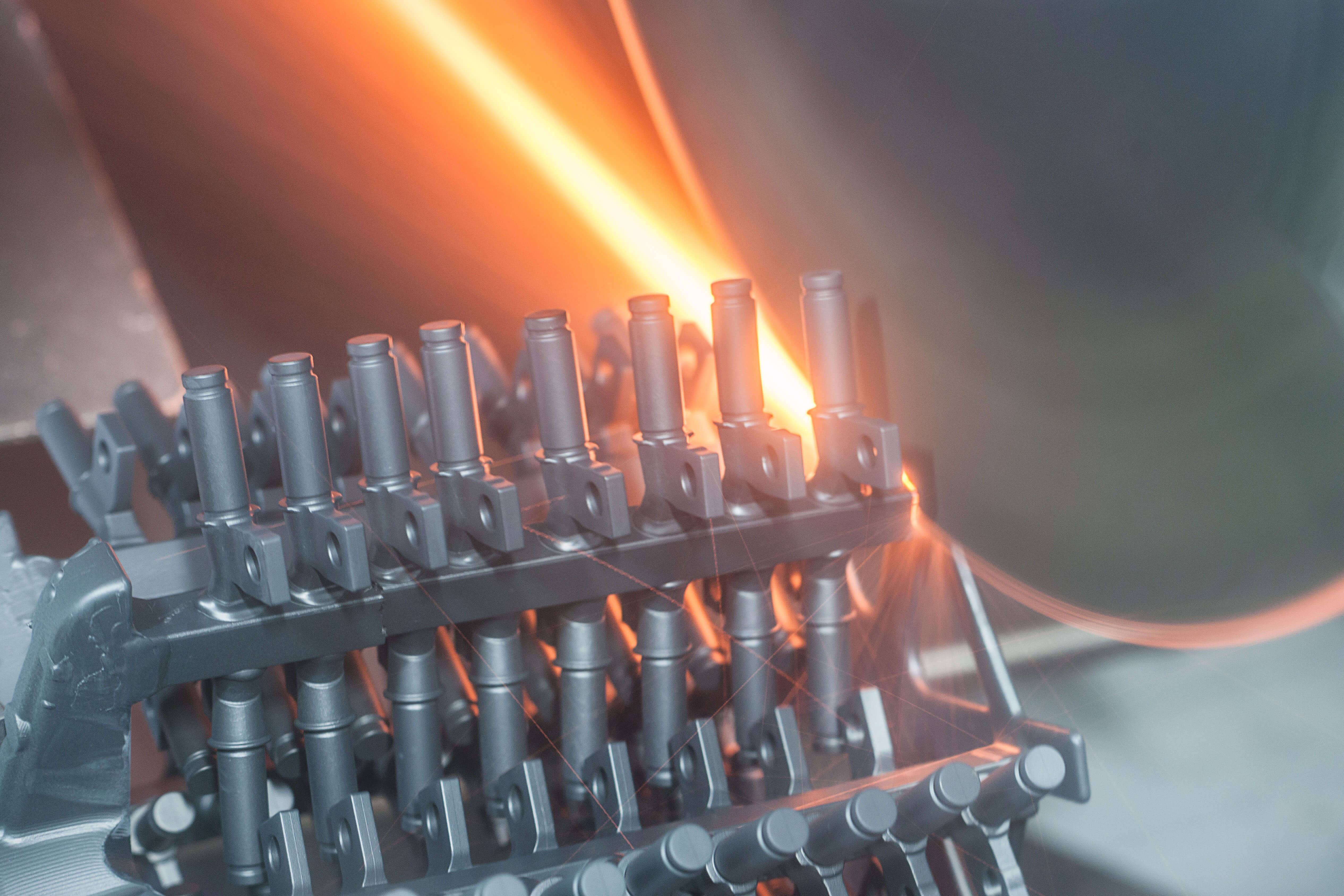

Investment casting describes a casting process used to produce precise & detailed castings. Various metallic materials can be cast, such as aluminium, iron, copper, cobalt & titanium. After melting down, these alloys are cast into prefabricated moulds. This results in investment castings that meet the demands of our customers at the highest level. Rarely, the process is also called precision casting or precision die casting. These names are due to the very tight tolerances that can be achieved in investment casting. Tolerances of 0.1 mm are possible for small components and approx. 0.5 % of the nominal dimension for large components. If tighter tolerances are necessary, these surfaces are mechanically reworked accordingly.

Investment casting is thus not only distinguished by its special process, but is also the optimal solution for meeting customer-specific requirements. Investment castings are used in a wide range of industries. These include, for example, the automotive sector , mechanical and systems engineering, food and packaging technology as well as pharmaceutical, medical technology and rehabilitation technology.

The special features of investment casting

The investment casting process brings with it some advantages that many are not aware of. Through the investment casting process, your products can achieve, among other things, a longer service life, a significant reduction in weight, improved surface quality, as well as increased economic efficiency. However, in many applications it is not recognisable at first glance that this is investment casting. It often happens that parts are produced using alternative manufacturing processes, such as machining, whereby intelligent investment casting solutions could be produced more economically at this point. Frequently, neighbouring components can also be integrated into the investment casting, in which case, functional integration must be mentioned. Let our experts check your components to see if investment casting is the more suitable process for you.

What makes FEINGUSS BLANK special

The investment casting specialists at BLANK are at your side right from the start. You benefit not only from our know-how in the manufacturing process, but also from our service as a development partner. In this way, we supply you worldwide with specially developed prototypes or series investment casting products in a wide range of industries.

At FEINGUSS BLANK, your needs come first. We ensure the technical feasibility of your complex products at economically attractive conditions and outstanding quality. See for yourself – become a fan of FEINGUSS BLANK, the foundry made in Germany!