We are better together! And, we now operate globally under the name Texmo Blank. You can find more information on our new website:

Until we launch the full version of our new website, you will continue to find details about investment casting as well as jobs vacancies on this page.

Investment casting for pharmaceutical technology, rehabilitation technology and medical technology

FEINGUSS BLANK - the safe solution for your healthcare application!

This is why FEINGUSS BLANK is your supplier for the medical industry:

- biocompatible alloys

- optimized geometries

- minimum tolerances of the components

- high strength and lightweight construction of the products

- highest surface quality and internal quality

- implementing the requirements for corrosion resistance

- customised solutions and material specifications

Do you like to realize a smart planning together with us?

Please contact us!

Contact

FEINGUSS BLANK GmbH

Sales

sales@feinguss-blank.com

P: +49 7371 182-0

We are experienced manufacturers in medical technology (medtech sector) and supply customers reliably and flexibly with investment castings used in the healthcare sector. Whether investment casting solutions for surgical equipment or in pharmaceutical and rehabilitation technology - FEINGUSS BLANK always has the right implementation idea and is also aware of the responsibility that the manufacturing of medical products entails. That is why we meticulously adhere to the applicable requirements and regulations of the industry branch, especially regarding the applicable demands on product quality, grade and hygiene. Quality assurance for investment castings in medical technology can therefore be mapped completely in-house for all common materials which distinguishes the BLANK-Group as a supplier to this industry.

Our investment casting process, also known as lost wax investment casting, makes mechanical finishing steps superfluous in many cases, as the components already have almost net-shape geometry after casting. This enables us to achieve enormous cost savings for you and still ensure the highest dimensional accuracy and quality. This makes the process particularly interesting for materials that are difficult to process. BLANK also provides you with a free tool for selecting the right material: the BLANK-material-app "SMART MATERIAL".

Through years of experience and continuous development of our production and processes, we are known as a manufacturer and service provider far beyond the foundry industry. Individually adapted customer solutions with lightweight construction character, with high strength and best corrosion resistance, represent the decisive challenges for housings, tripods and prosthesis production. FEINGUSS BLANK can sustainably improve the quality of life of patients by producing medical investment casting products. For this purpose, we use the alloys and materials known in the industry. 3D printing in wax turns out to be a particular advantage. With this process, the wax models are produced additively instead of relying on parts out of the tool. By eliminating the tool production this process is significantly faster and profitable even for small quantities. We look forward to tackling your next investment casting project in medical technology together with you!

Investment casting products for pharmaceutical technology, rehabilitation technology and medical technology

Runner made of investment casting

Medical facilities

This component is used in the production process of infusion agents. The highest demands are therefore placed on the material with regard to medicine compatibility which FEINGUSS BLANK realises with a smart lightweight solution made of corrosion-resistant stainless steel. We can implement the complex geometry exactly with our precision casting.

material:

stainless steel

weight:

770 g

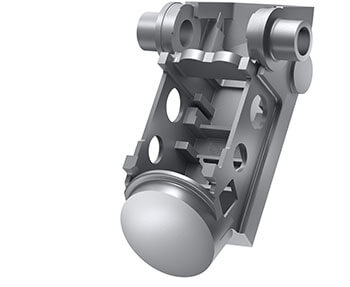

Case made of investment casting for operating application

Surgical device

As to components for surgery, the challenges lie in the choice of materials with regard to allergy compatibility and absolute sterility. Our application engineers have solved these requirements with a very complex and filigree component geometry.

material:

Aluminium alloy

weight:

1.000 g

![[Translate to Englisch:] Hüftpfanne](/fileadmin/user_upload/Hueftpfanne_Homepage.jpg)

![[Translate to Englisch:] RTM-System](/fileadmin/user_upload/RTM-System_Homepage.jpg)

Medical implants – Hip socket /acetabulum

New in the manufacturing portfolio since 2020 are medical implants. The range produced includes both hip sockets and components of a surgical set in various sizes. The replacement of a loosened or worn hip prosthesis is called hip prosthesis exchange or hip prosthesis revision. The indication field of the developed hip sockets are precisely these hip revisions as well as complex defect situations such as hip dysplasia.

The surgery sets, on the other hand, cover interventions for tumour diseases. The special feature here is their modular structure which allows doctors to select and use individual components depending on the characteristics of the bone sections to be replaced.

FEINGUSS BLANK decided to set up a separate production line and to use the centrifugal casting process in order to meet the qualitative and geometrical requirements of the hip sockets in the casting.

The hip socket casting consists of a massive bowl-shaped head, on the surface of which are hundreds of small so-called tripods. These fine, cross-shaped anchors are the link between the implant and the bone allowing the socket to be implanted without cement. So the structure ensures hold and strength of the implant in the human body, the so-called primary stability. In the long term, the bone grows into this structure which leads to additional stability.

Before working with us, the tripods were glued to the socket by hand in the wax part which was very time-consuming and made each implant a unique piece. Within the project implementation, FEINGUSS BLANK was able to achieve a realisation in wax 3D printing which enables a placement of the tripods accurate to a tenth of a millimetre. This method of production enables a better distribution of the tripods, a more secure mechanical connection between tripods and hip head, procures continuity to the process and achieves a reduction in personnel costs.

The hip sockets are manufactured in a variety of sizes and executions. In addition, the surgical sets are composed of over 200 individual parts. A cobalt-chrome alloy is used for all investment castings. Unlike the hip sockets, the system components are manufactured using atmospheric casting. Due to the variety of different parts (different sizes, right/left variants), each individual component has different requirements that have to be taken into account. The challenge here lies particularly in the process-safe casting of the material.

material:

Cobalt-chrome

weight:

depending on the size and execution of the hip socket approx. 180 g I depending on the size and execution of the RTM system approx. 200 g